The ALPHAFLEX™ filter panel

Increasing drum filter capacity by up to 20%

The patented Hydrotech ALPHAFLEX™ panel is a breakthrough in filter panel design. It increases the capacity of existing drum filters by up to 20% and saves up to 80% of the water in the solids trough picked up by traditional filter panels.

Upgrade your drum filter capacity by 20%

Boost your filtration system with the Hydrotech ALPHAFLEX™ panel. It increases the capacity of your current drum filter by up to 20% while saving up to 80% of water compared to traditional filter panels.

Efficient filtration, reduced energy consumption

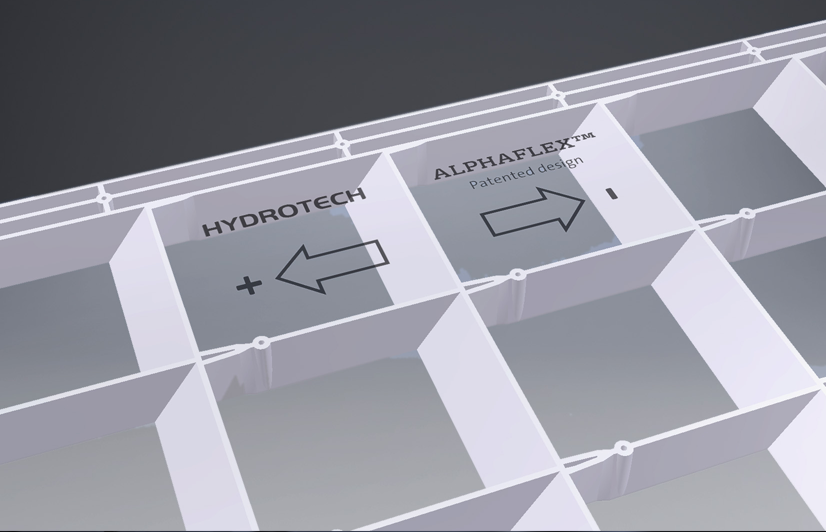

The patented design featuring the innovative angled horizontal walls allows the ALPHAFLEX filter panel to be mounted with either lifting (+) or releasing (-) characteristics. The combination of having some panels lifting (+) and some releasing (-) saves both energy and water.

Adaptable to your needs

Because of the angled walls, the ALPHAFLEX filter panel swiftly captures undissolved particles, enhancing the filtration process. Its adaptability makes it compatible with your existing system, addressing your current filtration requirements.

Quick and hassle-free assembly

Equipped with an integrated rubber gasket, the ALPHAFLEX filter panel ensures fast and easy assembly and replacement, minimizing the risk of leaks between the drum and filter panel.

Compatible and efficient

The ALPHAFLEX filter panel is backwards compatible with most drum filters and fits with existing Hydrotech drum filter models. With a larger filtration area and superior particle removal, it outperforms other alternatives on the market.

The angled design of the horizontal walls allows for easy determination of the amount of water each filter panel should transfer to the sludge tray. Adjust the filter panel by lifting or releasing it, depending on the application.

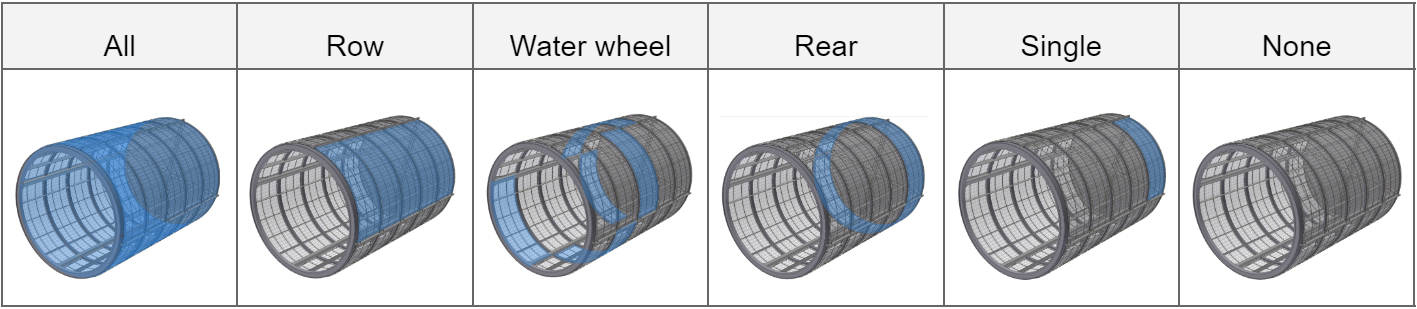

Panels orientation

Six panel orientations were tested, with different numbers of lifting (“+”) panels and positions along the drum. The setups are summarized in the table below, where “+” panels are highlighted in blue. In addition, the drum was equipped with the panels with the previous Hydrotech frame design, named PPW henceforth.

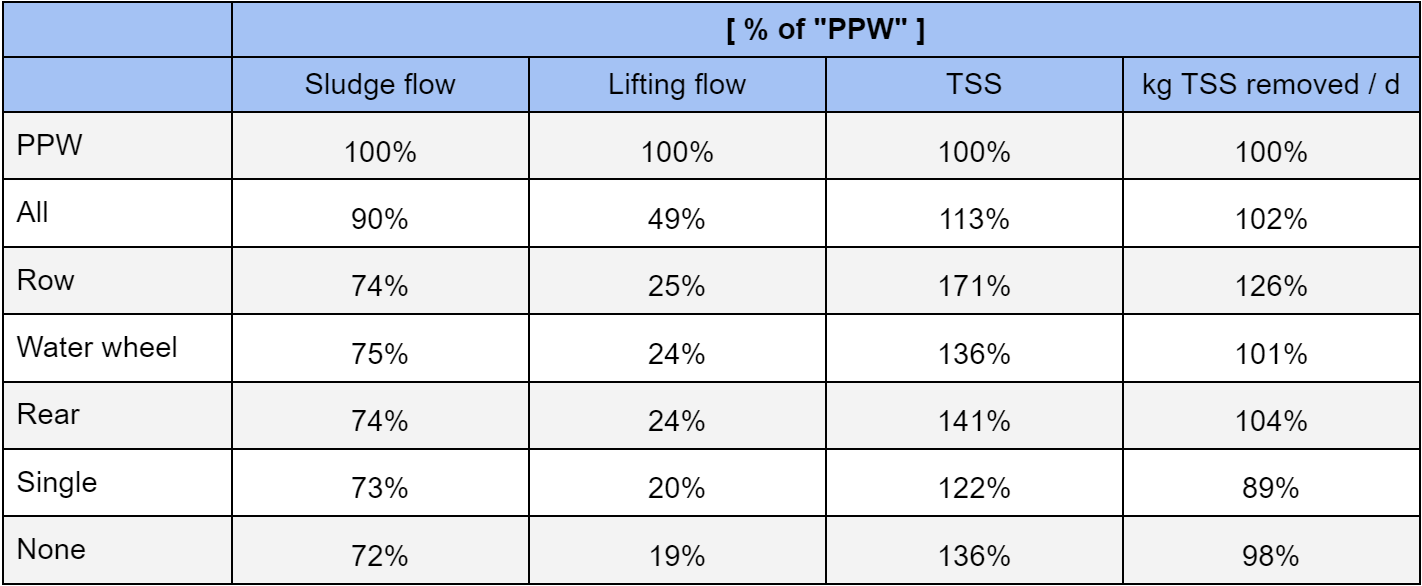

Process performance

The results were plotted as a percentage of the value measured for the previous panel design. The sludge flow, generated by both backwash pump spraying and drum rotating, can be about 25% lower with optimized ALPHAFLEX™ panels than with the previous PPW design, while when considering the lifting flow only, such as the flow generated by the drum rotating without backwash pump spraying, the difference can be up to 75-80% of the flow. The major impact can be seen on the solids concentration in the sludge, which is always higher when using ALPHAFLEX™ panels, up to 70% more concentrated with the best configuration.

Summary

One row of ALPHAFLEX™ panels lifting is the recommended configuration for a fish farm. It generates 25% lower sludge flow while increasing its solids concentration by 70%, as shown in the performed test. This is achieved by reducing the water volume lifted by the panel rotation by 75%, but the solids can be extracted more efficiently thanks to the improved panel design. Nevertheless, it should be noted that results can differ based on the particle size distribution of each system, therefore the presented outcomes should be considered just as guidance, and the best-performing panel configuration can be identified by on-site testing.